An interesting commission to create a wall panel/carving in Butternut of a Bonsai tree. The client furnished the design concept.

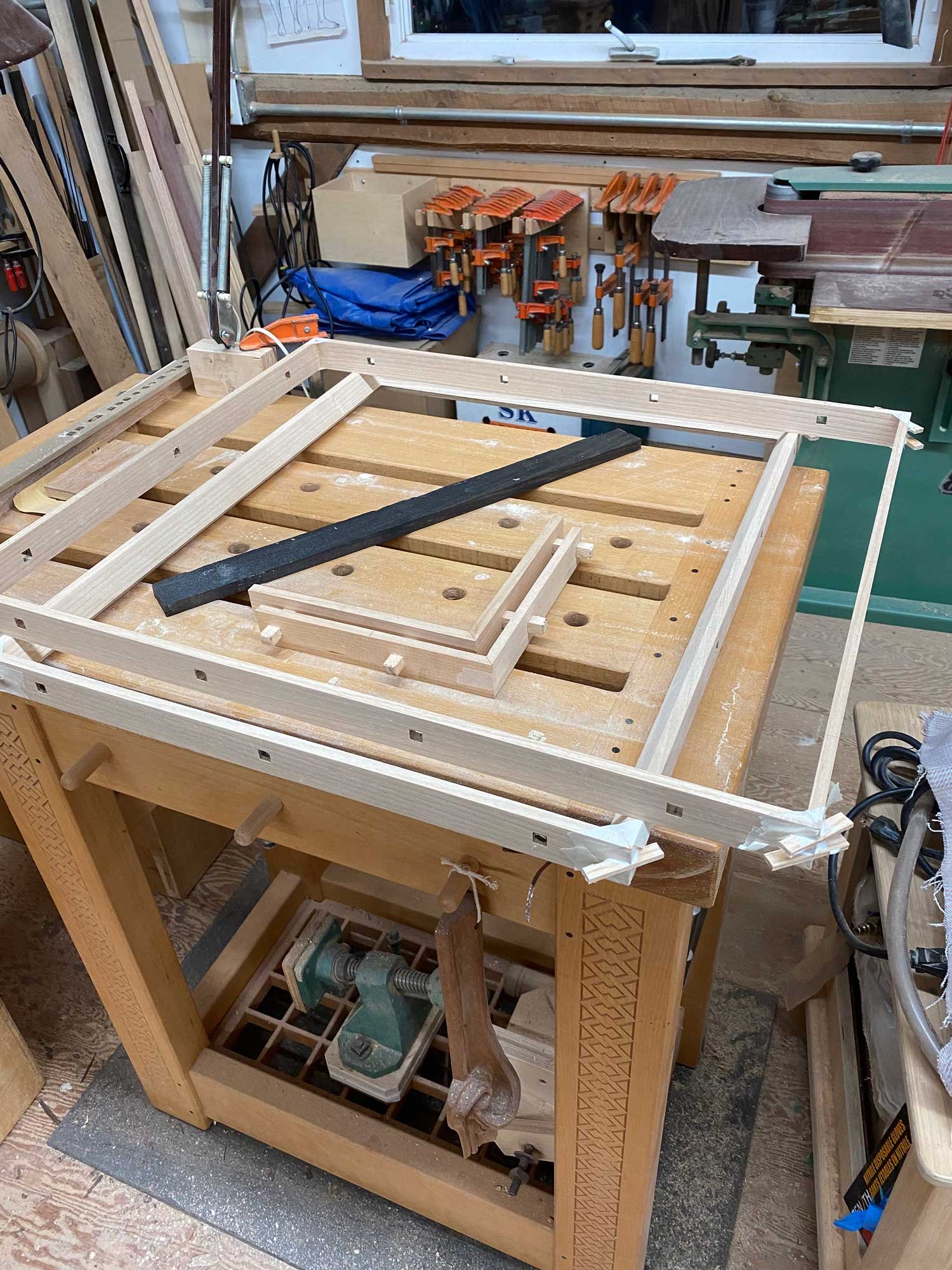

The initial excavation around the tree was done with a hand-held router. Unfortunately, I was waiting in line for cataract surgery and my vision was getting worse by the day.

The roughed-out design and background.

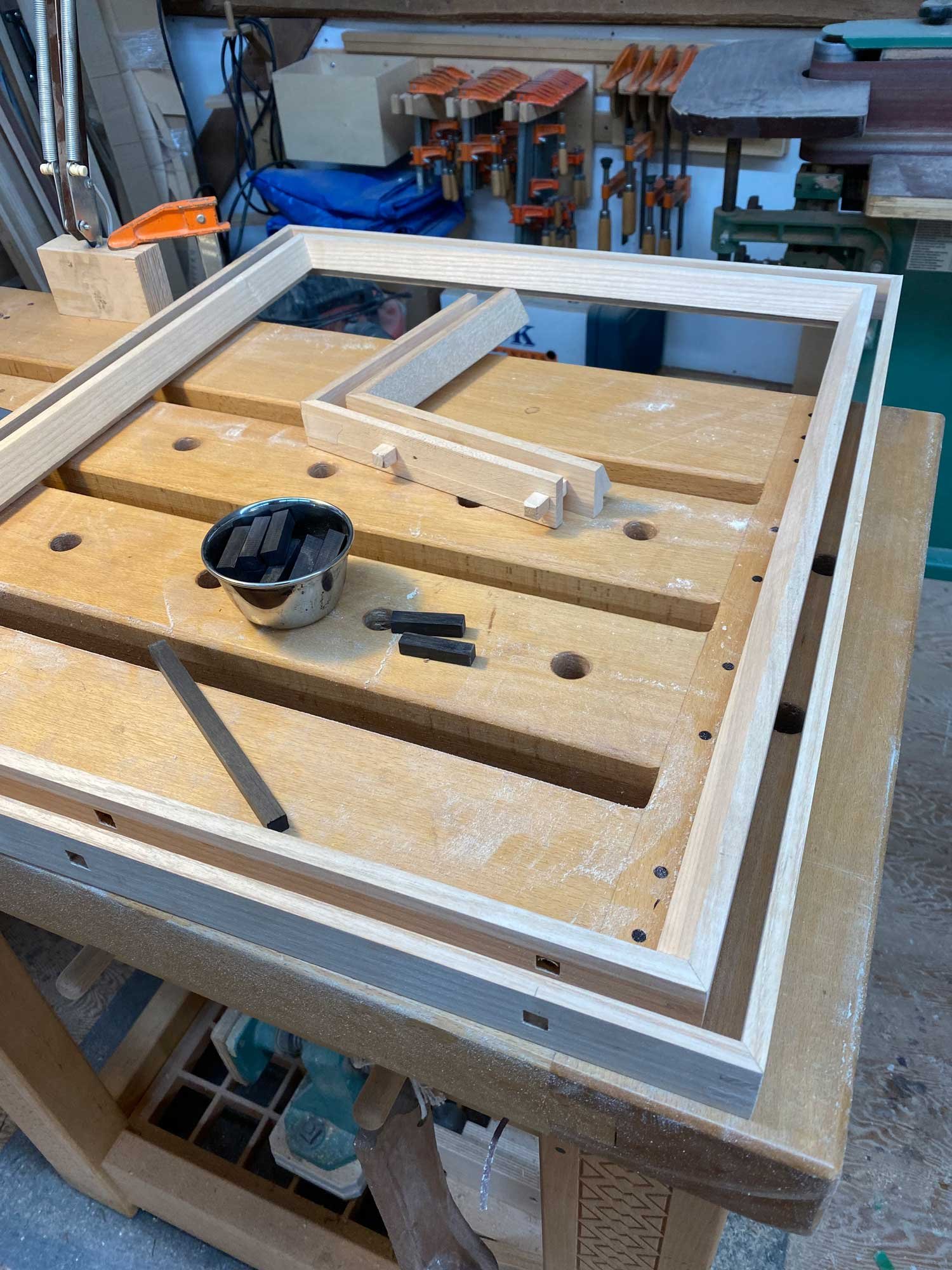

Here I am trying to decide on the relative heights of the different areas of the “tree”. It was at this point my vision had gotten so poor I decided to seek help from my friend Neil Cox, a wonderful carver.

With Neil’s help we found a “style” for the foliage we liked which allowed us to work the foliage in clumps somewhat similar to a Pine Tree. Neil roughed out the foliage while I had my first eye surgery.

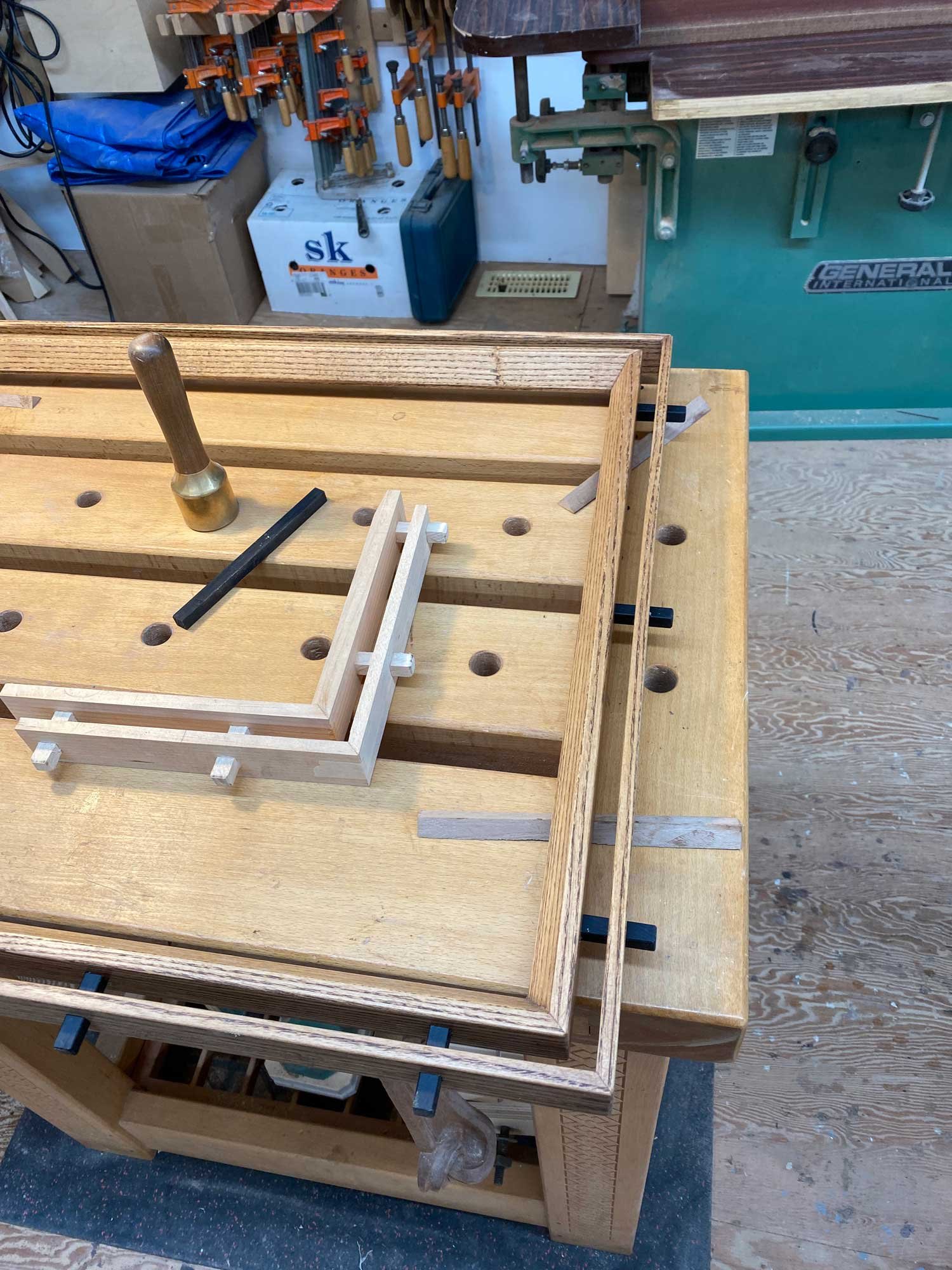

Here I am lowering the background a little more after most of the carving was done.

Next came a period of careful clean up and undercutting. By this time both my operations were over and my eyesight was like new.

A first coat of oil applied. I added Neil’s name to the carving in thanks.

The completed carving mounted in place in the sunroom of my client’s home.