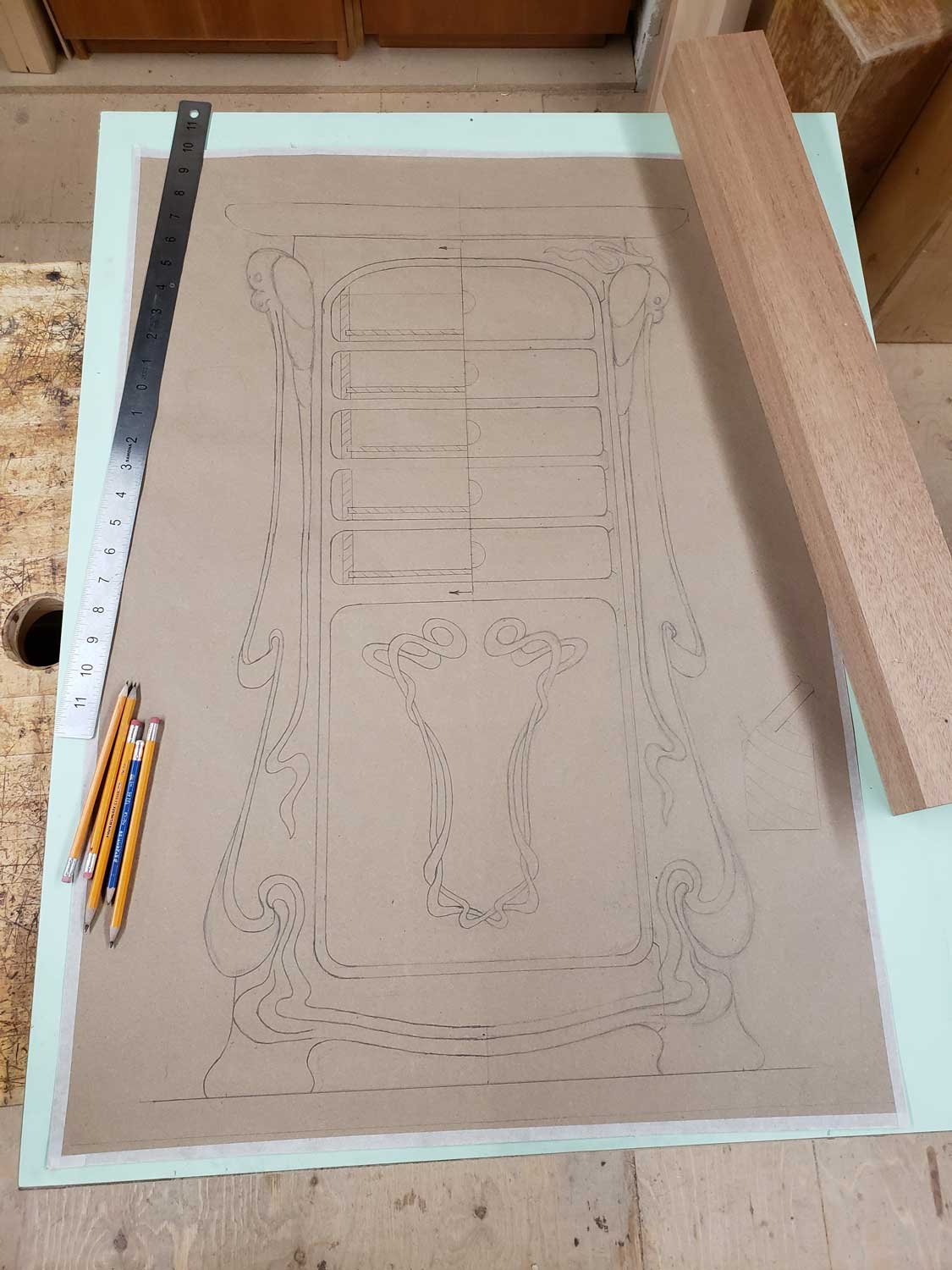

1. A prototype was commissioned by the customer for approval.

2. Once approval was given the glue-up process in White Oak was begun.

3. The blanks were band-sawn to shape and secured to wasters.

4. Basic layout of the blank being shaped.

5. The blanks were carved in stages with a close eye to the prototype.

6. The surfaces were carved relatively cleanly at each stage of work.

7. The completed Corbels were then fixed to a bracket.

8. The matching Corbels ready for the finisher and then installation.