A commission for five tables in what has recently come to be called mid-century modern furniture. The customer wanted walnut for the tables and a natural finish. The box type construction lead to a combination of veneer and solids.

I was able to use the last of an old walnut flitch I had in the shop on the outsides of the carcasses. The material was laid out so the grain ran continuously around the corners. The customer wanted to use an existing knot as the defining feature on the tables. Unfortunately the actual knot was missing so I had to punch a series of similar looking knots to fill all the holes.

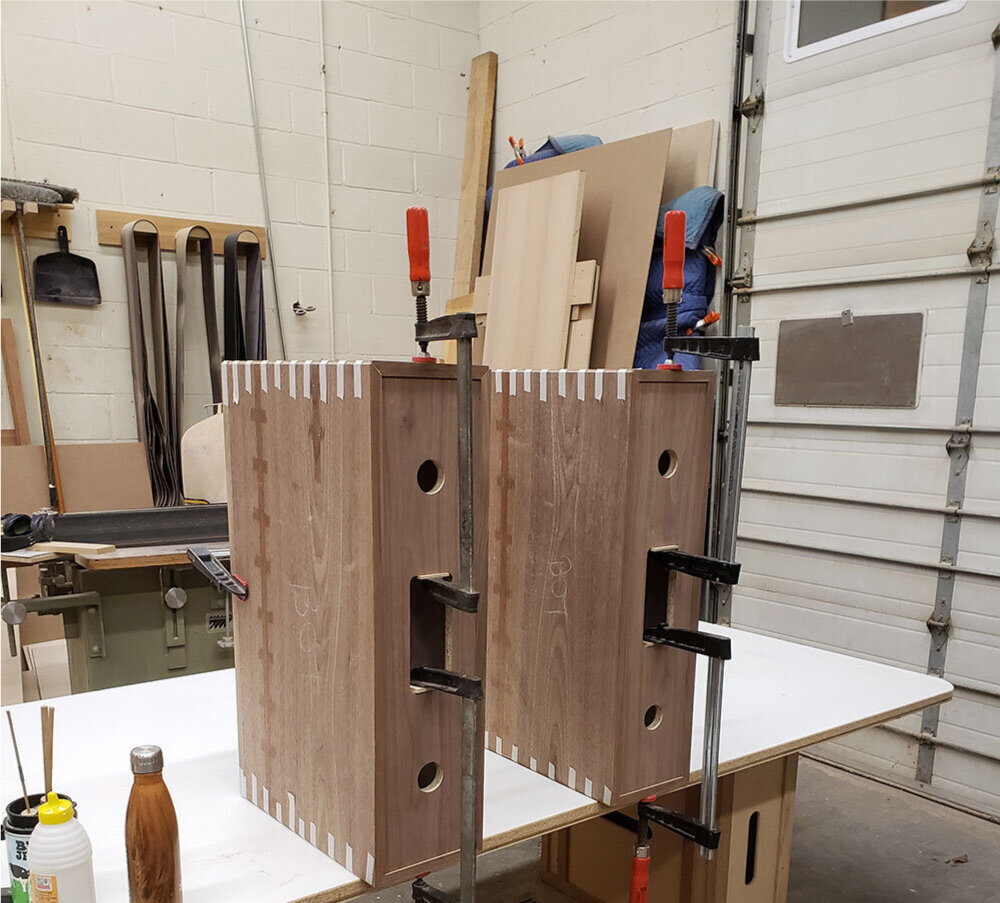

Here you see all the panels pressed up and ready for tape removal.

The panels have all been cut to size and the solids milled up.

The corners of the carcasses were mitred but I left a small square corner so that a strip of solids could be glued in to protect the edge.

The two 30” tables are all glued up with the edging applied and the 60” table is being glued up.

The 60” table all glued up with the edging added and the 72” table is being glued up.

Gluing up all the drawer sides.

Drawer boxes are glued up and being sanded.

Gluing the solid edging on the drawer fronts.

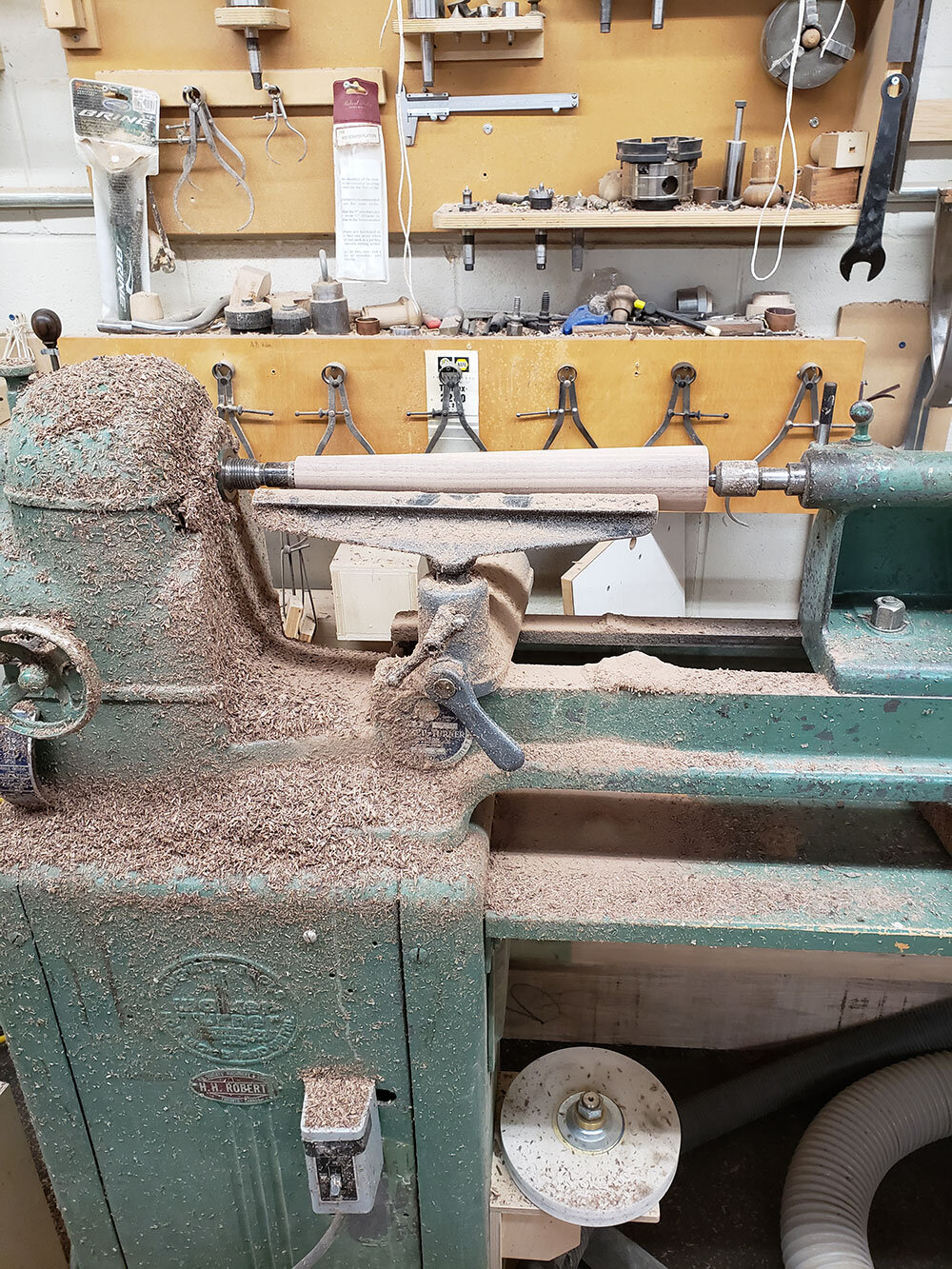

Turning the tapered legs on my lathe. There were three different lengths of legs.

Sanding the legs with the dust collector in place.

At this point the customer came back to the shop to determine the angle for the legs. The tape outline on the bench sets the bottom parameter.

Because the legs were tapered I decided to cut a full mortice for the aprons to sit in. I built a jig for the lathe to guide a router.

The legs with the initial mortice.

The first glue up of aprons and legs.

Trying to optimize space for the other sets of glue ups.

The first table being glued up. The leg assembly was surprisingly strong for being so light.

The larger tables had internal stretchers to help prevent movement.

Flushing the top of the structure on the shaper using a sanding disk. The corner glue blocks had been added by this point.

Mounting the drawer slides and fitting the drawer boxes.

Positioning the drawer fronts.

Cleaning up the bases prior to staining.

Staining and finishing.

The finished product with the handles installed.

All the drawers wrapped and ready to go.

All the tables wrapped with blankets and the legs shrink-wrapped about to be loaded into the truck. The care taken in wrapping and delivery mean an easy install on-site.