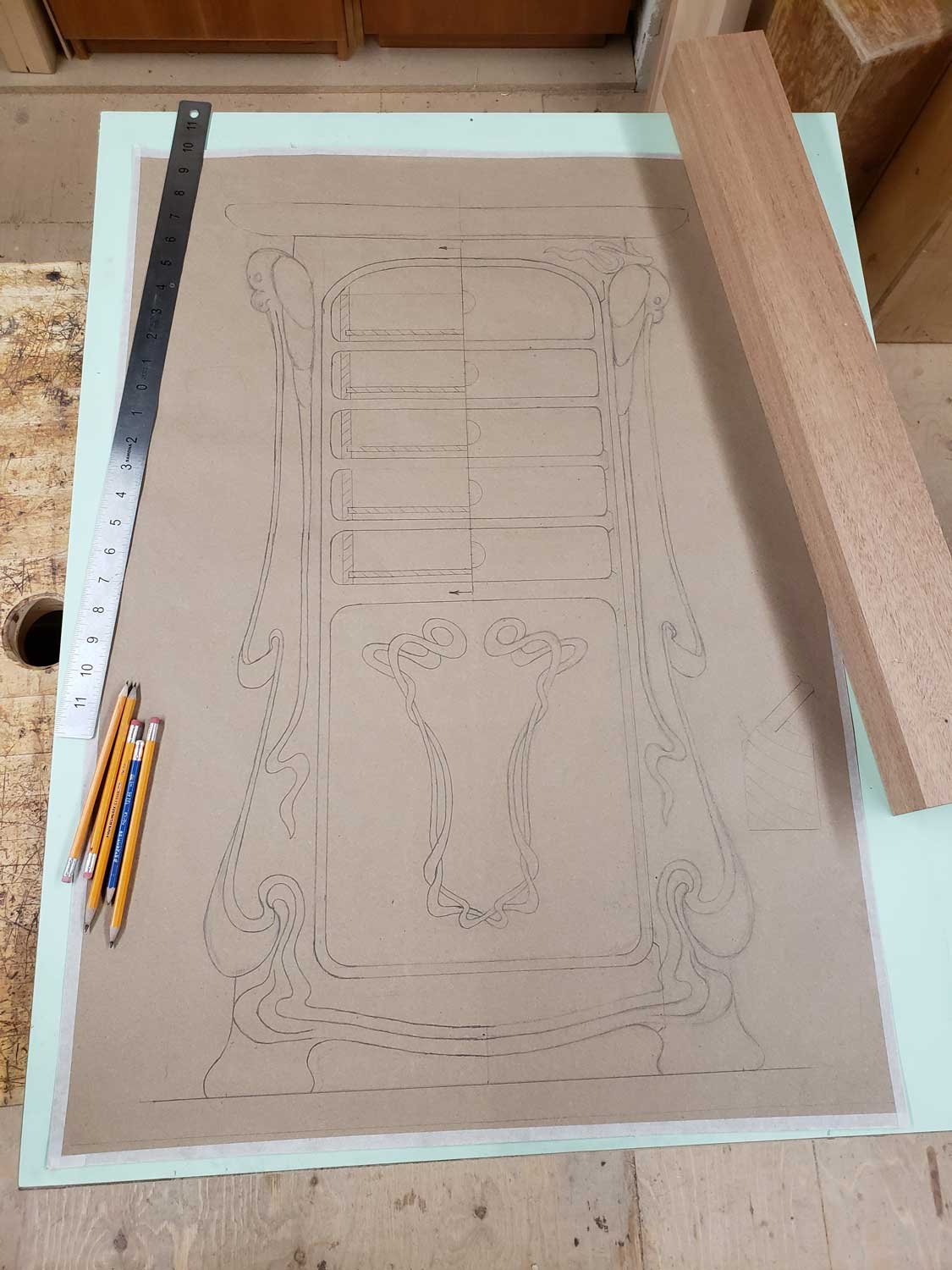

An interesting commission for lamp shades that turned out to be more difficult than I thought.

01 – The initial design and two of the cardboard templates used to mark out the plywood.

02 – Marking out and bandsawing the half rings.

03 – Cutting through a pile for one layer. The half rings are seen in the background. I was cutting for ten lamps at a time.

04 – Careful cutting with the table on the bandsaw tilted would mean less work on the lathe later.

05 – One level of half rings glued up. Three more waiting.

06 – Gluing up the initial levels before they are put on the lathe and cleaned on the inside.

07 – The initial portion of the lamps ready for another layer.

08 – Gluing on the next layer.

09 – The lamps are growing nicely.

10 – More rings, more glue–ups, more inside cleaning on the lathe.

11 – More than half way. Things are going well.

12 – Final glue-ups. Have to use larger clamps now.

13 – A plug on the end allows me to clean the outside of the lamp all at one time.

14 – The plug removed for a clearer view. The wall thickness is under a quarter inch and uniform.

15 – Applying a wipe-on finish.

16 – Wet sanding on the lathe. A bit messy.

17 – Wrapping for transport so the first ten can be installed.

18 – The lamps can be tested while the kitchen is being refurbished in stages.

19 – Different types of bulbs produce different effects. Who would have guessed?