A commission for an African Mahogany egg cut into two halves and hollowed out.

01 – The original plank which was left over from another job.

02 – The segments machined to thickness.

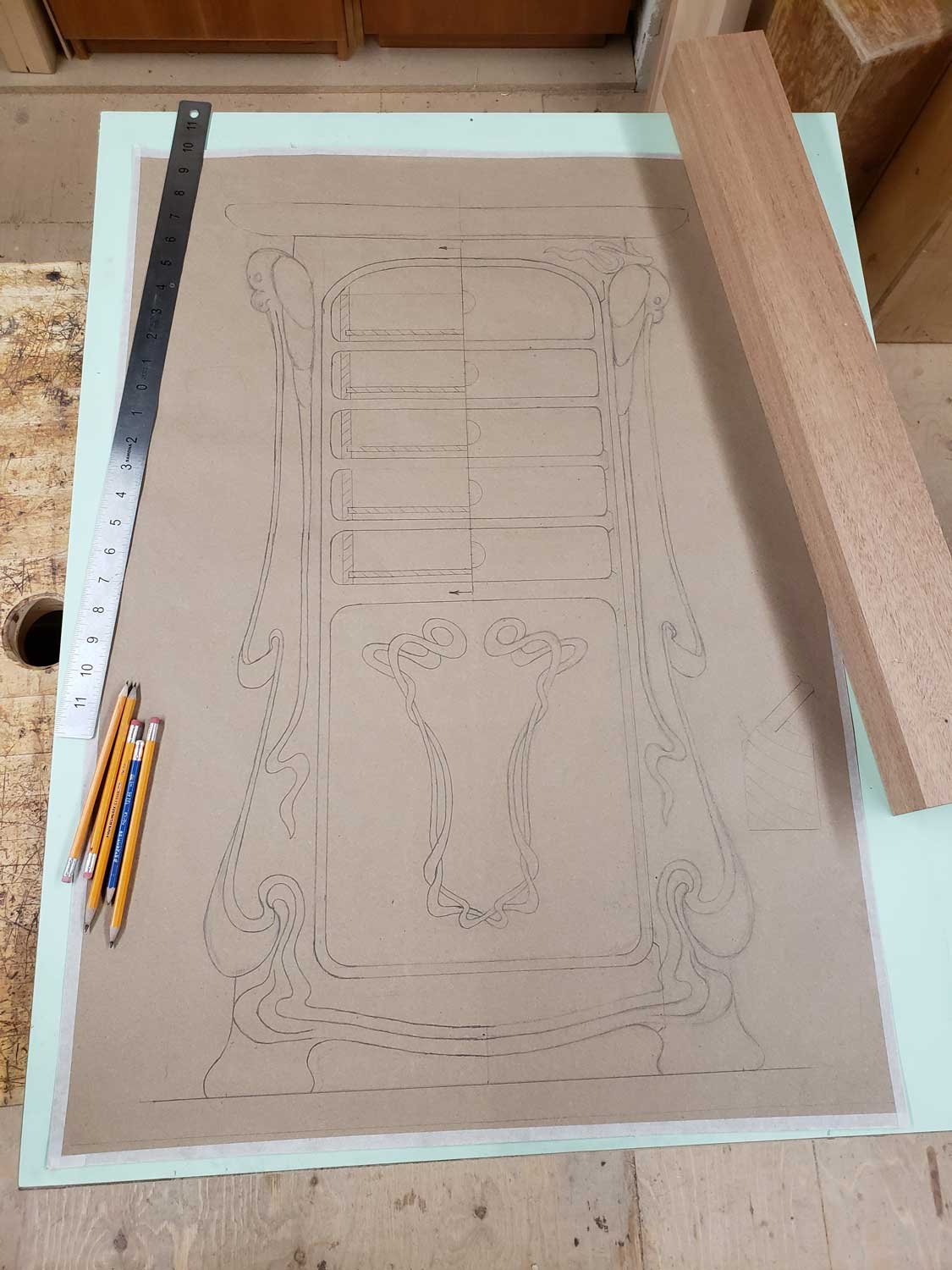

03 – Checking against a template drawn to the customer’s specs and trying to guess what the grain will look like after the blank is turned.

04 – Gluing up the blank.

05 – The corners are trimmed on the table saw.

06 – The blank is mounted on the lathe and turned to a cylinder.

07 – Marking out and turning in stages.

08 – Almost done.

09 – Sanded clean. Horns are left on the ends for attaching the egg to a bandsaw jig.

10 – Cutting begins on the bandsaw. The egg is supported by the jig.

11 – Help is enlisted to quickly tie the egg back together at the horn as the blade travels deeper into the egg.

12 – Almost through.

13 – A nice clean cut.

14 – The jig is re-worked to hold the egg on a sand bag.

15 – The egg is partially drilled out and then an angle grinder was used to clean out the rest of the material.

16 – The hollowed egg halves were to be used as deck covers for exposed parts on a mahogany boat.