1. A small commission for a TV stand in solid Cherry. I had been holding on to a number of boards in the shop for a couple of years. I hate to stock pile lumber so this was a great chance to put the boards to good use.

2. The boards pulled out of the corner of the shop all ready to go. A bit of 8/4 for the plinth.

3. All the components broken out. After the top was made up and the edge shaped I make a quick drawing in pencil on the underside to confirm carcass dimensions,

4. My old Lamello still working like a charm. The material is slightly oversized so I can thickness it after the glue-ups.

5. The glue ups are done carefully. The clamps are alternated from side to side to keep the panels straight.

6. The gables are broken out so the visible grain pattern matches on both sides of the carcass. Here the vertical face frames are being glued on.

7. Cleaning the bottom panel on the stroke sander.

8. A dry assembly allows me to check that all the components fit together.

9. The cabinet with the top in place just to check the overall proportions. I always have a little leeway with the customer and can still make slight modifications.

10. The glue up. Always check for square.

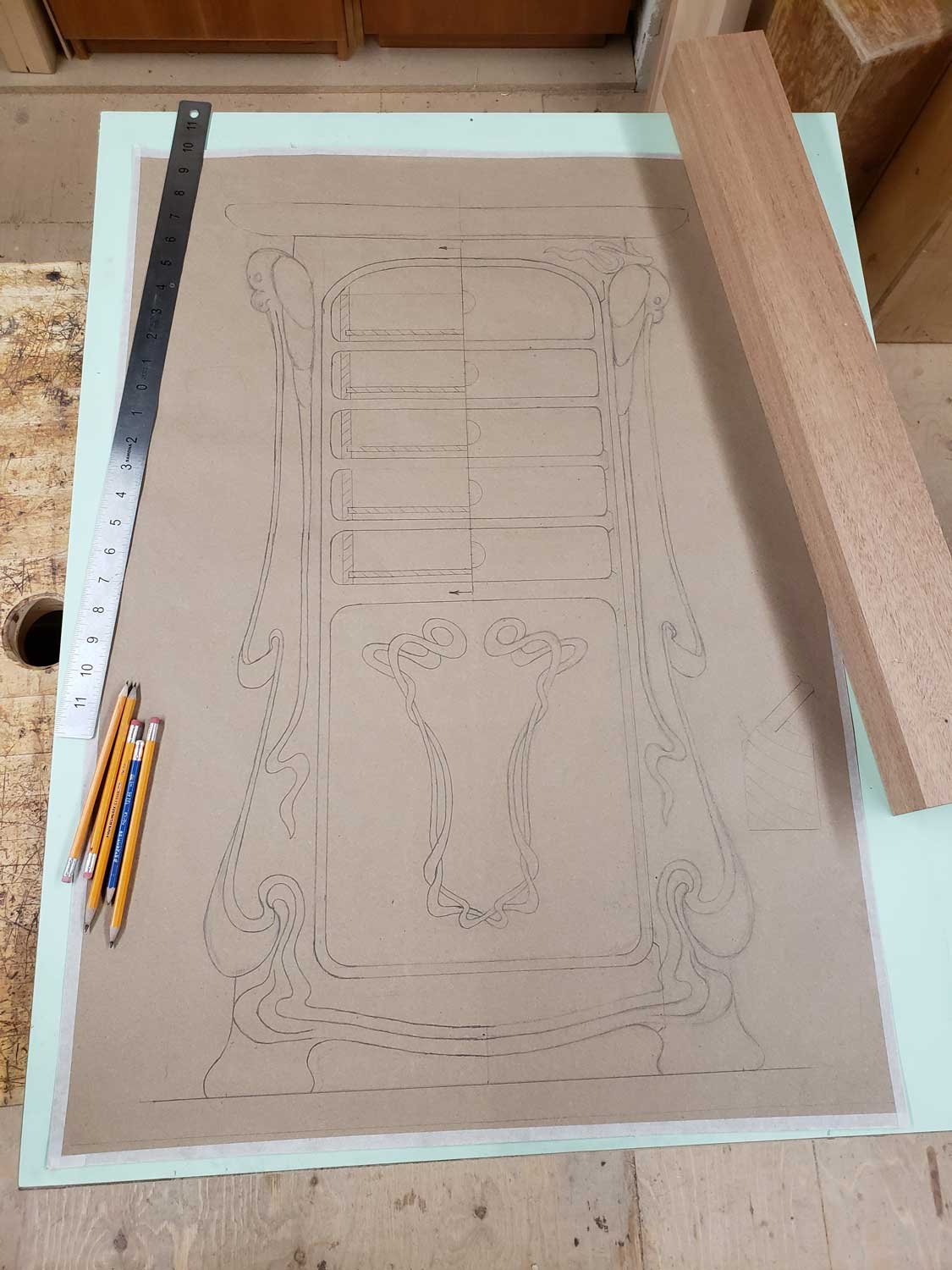

11. Laying out the door components to check the proportions.

12. Cleaning up the front face frames so I can apply the plinth. Sometimes the plinths are separate but in this case it was being glued on.

13. Gluing on the plinth. The components were pre-shaped and sanded.

14. Gluing up the doors. I pre-stained the backs of the panels and the areas of the front that sit in the grooves. I never want bare wood exposed because of panel movement later on.

15. Cleaning up the doors.

16. The carcass ready for the doors and back.

17. Fitting and hanging the doors.

18. Fitting the back. The back has openings for the plugs to run through and also to vent the cabinet.

19. The completed cabinet ready for final sanding and finishing.

20. I was matching the color of existing furniture in the room where the cabinet was going so I had to layer several colors to get it right. The top coat was old-school oil and wax which involves multiple layers, wet sanding and polishing and of course time.

21. Because the doors were longer than they were high I had decided to use some brass piano hinge I had around the shop. I decided to polish them up even though they looked nice with a patina.

22. The cabinet completed. I moved on to another job and just let the finish harden for a few days.

23. Wrapped up ready for delivery.