A design executed long ago as a group project while teaching in a local college.

01 – A cardboard mock-up of my intension.

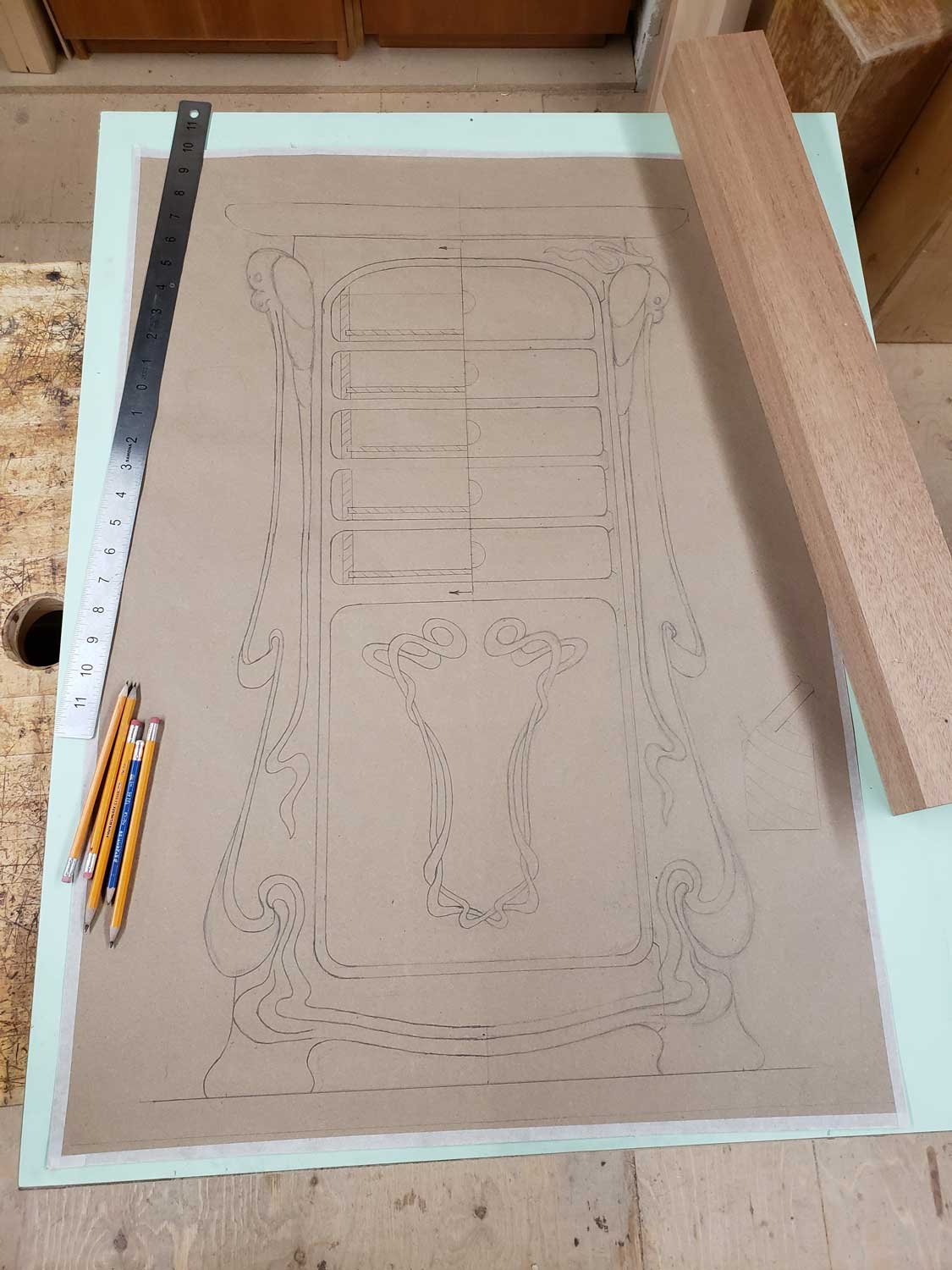

02 – Laying out the curves full-sized on the floor to get a sense of the scale.

03 – Pressing the veneer in a vacuum bag.

04 – Removing the veneer tape.

05 – Gluing on the solid edging involves lots of clamps.

06 – Trimming the edging with a router.

07 – Laying out a design on the surface.

08 – Routing close to the lines.

09 – Cutting to final opening size.

10 – Fitting the decorative veneer to the openings.

11 – Building up and trimming forms on the shaper.

12 – Gluing up the large arch.

13 – A few of the glue-ups of component curves.

14 – Thickness planning a curve always drew a crowd.

15 – Gluing up the sub-top.

16 – Assembling the outer structure.

17 – Many glue-ups for the inner supporting curves.

18 – Clamping the inner curves in place to get a visual.

19 – An end view. Very close to my original intension.

20 – Cutting and fitting the inner curves.

21 – The assembled sub-structure with half the top in place.

22 – A groove is cut for inlay.

23 – The completed table.

24 – Staining the top before spraying. The base was also stained.

25 – The completed table. Pretty close to my original intension.