An interesting commission for a large carved pedestal. The round top and foot of the table were to be granite.

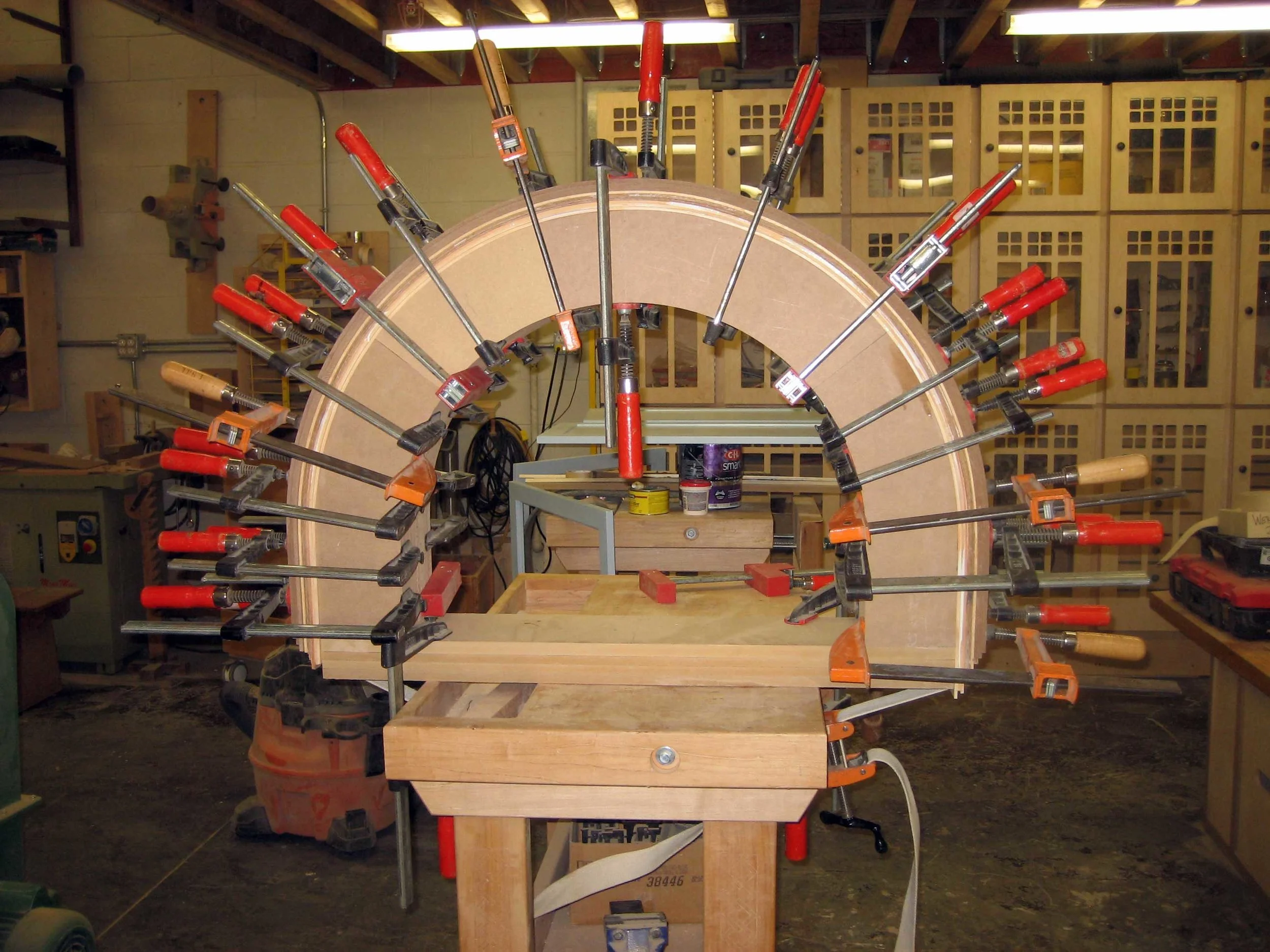

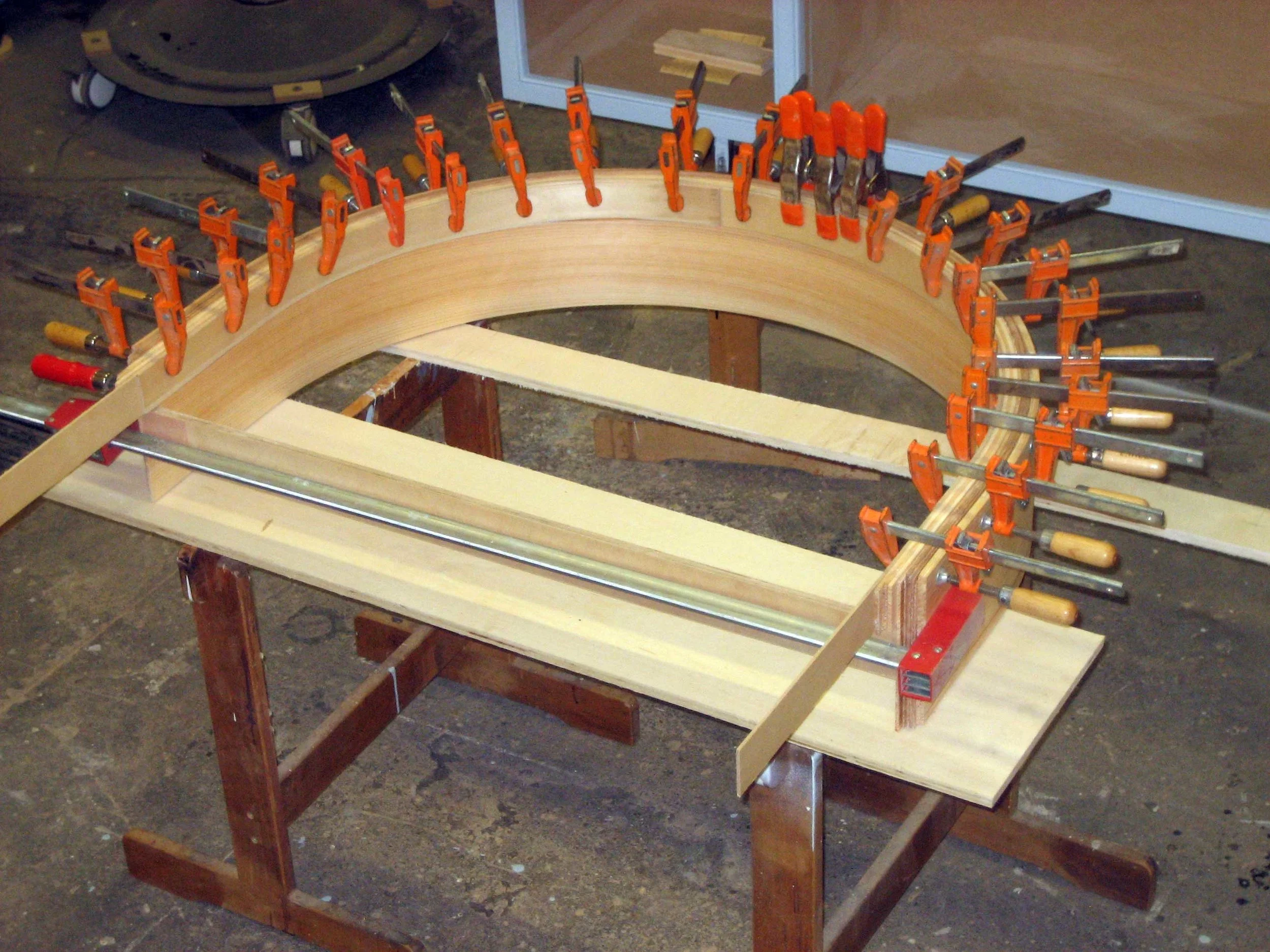

01 – The glue-up was done in two layers to give the volume need. Additional pieces were added later after the carving had begun.

02 – The completed blank. A 5’ diameter pipe would be inserted after carving bolted to large metal discs used to support the granite foot and top.

03 – The top and bottom of the blank are leveled using a router.

04 – The hole is covered with a plywood disc and a face plate attached.

05 – The blank is mounted on a lathe.

06 – Turning begins.

07 – Starting to take shape.

08 – The turning is completed. Sections are left flat where more material will be attached later.

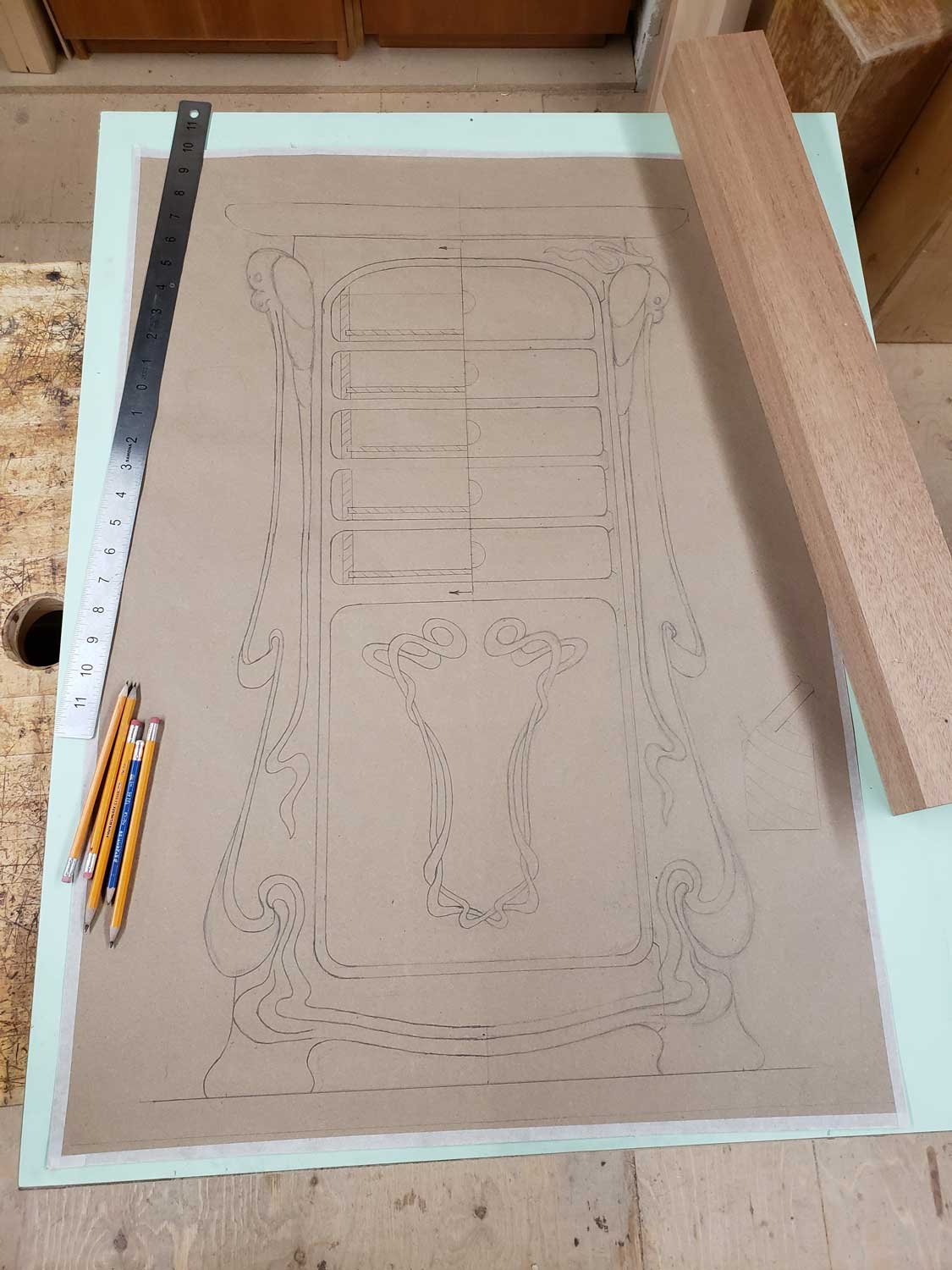

09 – The turning is divided into segments and a rough copy of the design sketched on.

10 – The carving is roughed out trying to retain a balance between repeating motifs.

11 – The shape is beginning to evolve.

12 – I moved locations in the shop and began the final stages of carving.

13 – Finding a balance.

14 – Starting the final clean-up in preparation for a paint finish.

15 – The other side.